Spoiler: Every Winemaking Operation Can Do These Things

The 2025 vintage is shattering assumptions and rewrote the rules – giving some regions a reminder what a good harvest feels like, and other regions struggled under accelerated conditions. While some producers clung to outdated practices (yes, that means you if you still think 65°F counts as “cold storage”), others embraced cutting-edge enological techniques in efforts to improve quality affordably. Like most years, this vintage became a real-world laboratory where I witnessed firsthand which approaches succeeded brilliantly and which still require some work. The lessons learned could be the difference between your next wine being merely good or absolutely exceptional.

New Yeast Nutrient, New Challenges

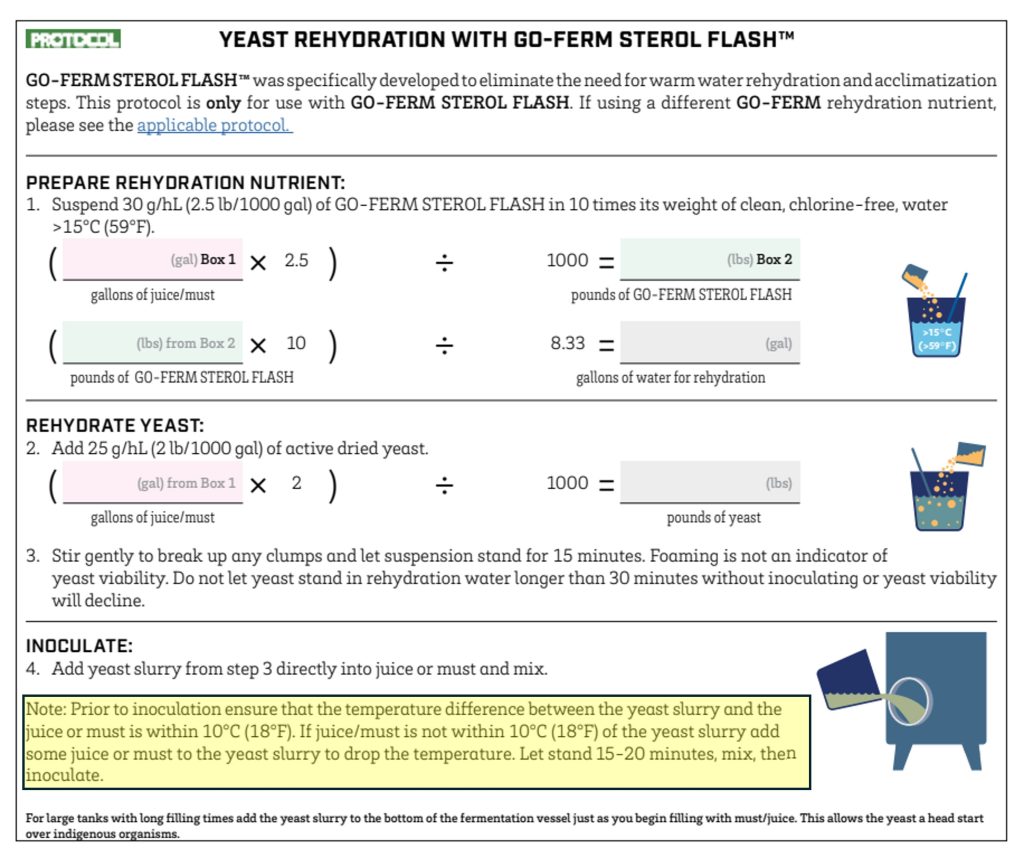

I saw a higher number of winemakers adopt Go-Ferm Sterol Flash hydration nutrient (sold by Scott Labs) in 2025 which is marketed as “less work” within a retained high-quality product. But with this integration, I found winemakers often need reminded to investigate beyond the marketing documents and read the fine print for new products.

While Go-Ferm Sterol Flash provides an opportunity for winemakers to skip the juice acclimatization step, as is marketed, it’s also true that for colder juices or musts, bringing the yeast/nutrient slurry within 10°C (18°F) of the juice/must getting inoculated is still recommended. You can find this information within the “Learning” material on Scott Labs’ website with regards to rehydration protocols with Go-Ferm Sterol Flash.

For those that missed the fine print, I did not notice any effects on the fermentations that negatively impacted wine quality. The only anecdotal observation I made was a small delay, usually 2 – 3 days, in the fermentation getting started. This “delay” is associated with the lag phase of fermentation kinetics, and that slower lag phase can be considered normal. Nonetheless, many winemakers have grown used to a shorter lag phase and the noticeable delay may have concerned them initially.

Another yeast hydration alternative for those winemakers looking to save time during yeast inoculations includes Enartis’s Nutriferm Energy product. Again, this would act as a substitution for the Go-Ferm products. The time saver with Nutriferm Energy yeast hydration nutrient is a lack of the traditional heating step associated with Go-Ferm or Go-Ferm Protect Evolution. Instead, instructions are to simply use “warm [chlorine-free] water” for hydration. Remember to always follow current supplier directions for their enological products, as directions are periodically updated over time.

Juice Handling and Temperature Requirements

During traditional juice settling by a pectinase enzyme, the suggested juice storage temperature is refrigeration, 40 – 45°F. For many, this temperature may seem unattainable, but the temperature recommendation stems from the fact that above 45°F is considered spoilage-temperatures or risky-temperatures (from a food safety perspective) for perishable products.

For wine grape juices (white/rosé) 65°F is optimal spoilage temperatures for many of the microorganism that exist naturally on grapes. Juice intended for fermentation lacks appropriate preservation, even if the winemaker adds SO2 to the juice during the settling stage. Most – if not all – of the SO2 added is going to end up bound, making its antimicrobial properties a moot point.

Nonetheless, once the juice is inoculated for primary fermentation, the 65°F temperature is usually appropriate for many styles of wine. But during juice settling this temperature can be risky, especially if settling is taking more than 4 – 6 hours.

What can you do if 65°F or higher is your normal juice settling temperature?

Winemakers should, first and foremost, plan out their harvest operations before harvest season begins. I see a lot more winemakers getting more comfortable with planning prior to the start of harvest. While unforeseen challenges do arise each year, having a plan does help winemakers pre-emptively expose gaps in their production and address them before grapes hit the crush pad.

Furthermore, many winemakers feel insecure about inoculating a juice or must that is at 50°F – 60°F, especially if this temperature range falls outside of the marketed ideal temperatures for their yeast strain. But many inoculations are successful within that range. If you have questions on this for a specific yeast strain, double check the protocols with the suppliers. They are usually very generous with their technical advice for their products.

Another option is to look for quick-settling enzymes that can clarify juice at quicker rates. I currently use Rapidase Clear Extreme (sold through Scott Labs) when warmer temperatures in the juice are eminent. This does require some planning, though, because if the enzyme goes into the [warm] juice in the morning, it will likely need racked and inoculated by early evening on the same day, depending on the juice temperature.

And finally, consider renting cold storage. I see this option becoming more popular with unpredictable grape delivery logistics and shortages for labor in the winery. Having a cold storage room (40 – 45°F), even if it is a rented space, can be quite advantageous for wineries. Plus, having a cold storage space provides options for wineries logistically, which can help reduce extended hours or the regularity of harvest stress during an unpredictable season.

Malolactic Fermentation (MLF) Completion is Not a Guarantee

It’s easy to make the assumption that MLF is as easy of a process as primary fermentation. But the reality is, MLF is actually a tricky fermentation to complete due to the conditions in which bacteria need to thrive. Lactic acid bacteria, the bacteria responsible for MLF, work under high a high alcohol and acidic environment. If winemakers added SO2 early in production, the presence of SO2 can also be quite inhibitive for malolactic bacteria to do their thing.

MLF success really comes down to the winemaker ensuring that the environment in which the bacteria grow (i.e., the wine) is as optimal for their growth as possible. This includes minimizing oxygen, ensuring the wine’s temperature is ideal for the selected bacteria, and making sure there are no competing spoilage microorganisms. I’ve previously spoken, at length, on these tips in the October 2024 Winemakers’ Blogpost: 5 Tips for MLF Success.

By the time many winemakers communicate to me that they are having issues with MLF, it’s almost too late. The VA could have risen significantly, making the wine quite spoiled or there may be a film, which makes it tricky for lactic acid bacteria to outcompete and dominate within the wine. Plus, restarting the MLF can be difficult. For any winemaker that has had to do this, they will attest to how horrible it is for them to attempt an MLF restart.

One key that I see many winemakers missing is that lactic acid bacteria thrive without oxygen. Both lactic acid bacteria and acetic acid bacteria like same wine temperatures for growth (usually above 58°F), but they have different oxygen requirements. To favor lactic acid bacteria growth winemakers need to minimize oxygen in and around the wine. In wines where oxygen is prevalent, acetic acid bacteria have a stronger opportunity to dominate as they need oxygen to grow.

Furthermore, do not get lazy with monitoring the MLF process. I see many winemakers opting out of monitoring primary fermentation because their lives get busy during harvest season. But monitoring the MLF process is essential to avoid mishaps. It’s expected that MLF can take at least a month to complete, so weekly monitoring is recommended to remain educated on what is happening in the wine. Paper chromatography is great for monitoring the progression of MLF over time. It’s easy, it’s relatively inexpensive, and winemakers can review multiple wines at one time. (For a review on what paper chromatography is and how to use it, please refer to the Winemaking Lesson: The Dot Races.) For winemakers that have turned to the Sentia, this is also a handy tool in watching the malic acid degradation over time as long as the initial malic acid concentration is within the Sentia specs. The Sentia is easy to use, but it can be costly for some operations.

Beyond watching malic acid degradation, winemakers should also monitor volatile acidity (VA) weekly to ensure acetic acid bacteria growth are not taking over the wine. While the VA does increase slightly (usually within 0.20 g/L acetic acid units) through the MLF process, large increases or rapid increases in VA are an immediate indication something is wrong in the MLF process.

The final part of this discussion is really strain selection and, probably, ensuring there is adequate nutrition for the lactic acid bacteria strain. While I have not always been a proponent of MLF nutrients, I have started relying on them more readily as more scientific information reveals their importance. This is probably one enological product worth purchasing if you know a wine is going to go through MLF. Additionally, I only recommend about a handful of MLF commercial strains to DGW Clients, and I tend not to experiment too much with this process. The reason for this is because reliability is often key for MLF. Many operations have gaps in their production (i.e., lacking tank temperature control, inadequate temperature and humidity for wines in barrel, a lack of appropriate tanks/vessels for MLF, etc.) that really drive a need for MLF to complete swiftly and completely. If you are in the market for trying out a new strain, I’d advise trying out the new strain on one or two ferments instead of the entire lot of wine for a given vintage. This is always how I recommend MLF changes to DGW Clients. Here, the winemaker can observe how the strain does under various conditions and if it is something that is going to work for their operation in future vintages. If something does go wrong, like a stuck MLF, then one or two batches of wine to try to restart is often easier to handle compared to 5+ batches.

Ready to have that expert voice in your corner?

Photo by: Savannah Smith Photography

The chaos of harvest has a way of hijacking even the most level-headed winemaker’s judgment—when tanks are full, timelines are tight, and something starts going sideways, the impulse to “do something, anything” can override years of careful planning. I’ve watched too many vintages get compromised not by lack of knowledge, but by panic-driven decisions made in isolation. The best winemakers I know have learned to recognize that critical moment when stepping back, taking a breath, and reaching out for a second opinion isn’t a sign of weakness—it’s what separates exceptional wines from expensive mistakes. Your grapes deserve better than hasty fixes, and so do you.

Ready to have that expert voice in your corner? DGW Elite membership connects you directly with seasoned winemaking expertise twice monthly—whether you’re wrestling with a specific fermentation crisis or want to dive deep into the broader principles that will elevate your entire program. Because the difference between a good vintage and a great one often comes down to having the right guidance at exactly the right moment.

The views and opinions expressed through dgwinemaking.com are intended for general informational purposes only. Denise Gardner Winemaking does not assume any responsibility or liability for those winery, cidery, or alcohol-producing operations that choose to use any of the information seen here or within dgwinemaking.com.